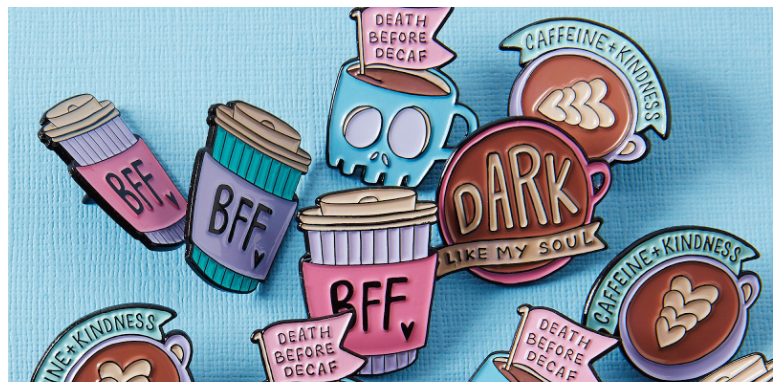

Enamel pins are one of the hottest trends of the moment and businesses, creatives and clubs are looking to get in on the game and create their own bespoke designs. Pins are worn for a number of reasons, from expressing personality and beliefs to showcasing appreciation for brands, bands and organisations, so a great enamel pin design is a must to ensure people wear your message. In this post, we’re going to look at how to make enamel pins, from the initial design to how we construct the pins at Enamel Pin Factory.

Enamel Pin Design

Whether you’re creating promotional enamel pins, collector's items or simply want to showcase your own creative talents, a great pin starts with a striking design. Even if you don’t have design skills, there’s plenty of tools available online to help you turn your ideas into workable designs for pins. Photoshop or Illustrator are the best tools to use to create your mock-ups, however, if you don’t have access to these you can use free alternatives to start creating your designs.

If you’re not confident creating your own enamel pin designs, you can always ask a designer for help. Check out freelance websites such as Fiverr or Upwork and find a designer who is able to bring your ideas to life.

How to make enamel pins

You’ve got your design sorted and you’re ready to turn them into enamel pins, so what’s the next step? The first thing to decide is whether you want to create soft enamel or hard enamel pins. The different materials offer different benefits, so it’s vital that you research which will be best for your brand.

When we create enamel pins, we use your artwork to create a unique die. This is then stamped into metal to create the recessed design which is cut out to shape for the base of the pin. The pin base is plated in gold, silver, gunmetal or black, then the recesses are filled with coloured enamel paint, separated by the tiny raised walls made by the lines you created at the design stage.

To create a soft enamel pin, one layer of enamel paint is applied to the recessed areas of the pin. Once this is dry, the pin sits slightly lower than the metal walls of the pin to give it a ridged finish. Soft enamel pins are a cheaper option to produce and are ideal if you’re creating pins for promotional events. Although they are hard-wearing, they’re less durable than their hard enamel counterparts.

To make a hard enamel pin, the enamel paint is applied in multiple layers to the recessed areas of the pin. The paint sits level with the raised metal walls and the surface created is smooth and flat. The paint is then set at a high temperature and polished until it’s glossy, this gives it an exceptionally durable, hard-wearing finish.

How much do custom enamel pins cost?

The cost of creating enamel pins is dependent on a lot of factors, typically, buying in bulk will ensure you keep your costs down, however, you need to ensure you’re using a reputable service to get the most from your money. If you’re looking to create multiple designs in one batch, this can also increase the overall order value, as will adding additional extras such as backing cards for presentation. Before you order your enamel pins we recommend ordering a sample option to ensure you’re 100% happy with the design before splashing the cash. You can also speak to your manufacturer about custom options such as the colour of the material used for the clasp.

If you’re planning on making your own custom enamel pins, we’re here to help. Our dedicated team is there every step of the way, whether it’s approving artwork, advising on the type of pins you need and taking care of all the additional extras you need to bring your artwork to life. We’re basically here to offer the same advice we wanted when started out, so you’re in safe hands!

Get in touch if you have any questions about how to make enamel pins today.